Download document () of 20

Download

You have exceeded the download limit

Transmission maintenance is an essential part of overall truck maintenance, impacting both performance and longevity. Whether you’re managing a fleet of trucks or operating a single heavy-duty vehicle, understanding transmission care is key to minimizing downtime and repair costs. This article will cover best practices for transmission maintenance, highlight signs of potential issues, and explore how advances in transmission technology are transforming maintenance schedules.

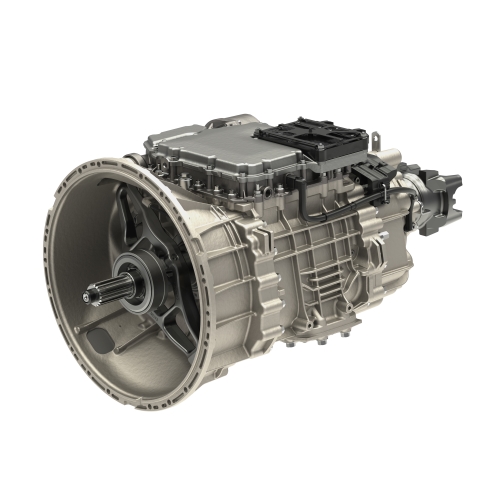

In any vehicle, the transmission is responsible for transmitting torque and speed from the engine using ratio sets to deliver power to the axles/wheels efficiently. Heavy-duty trucks, especially those involved in line-haul and vocational applications, put immense strain on their transmissions due to heavy loads, varying terrains, and extended operating hours. Regular transmission maintenance helps to ensure smooth operation, improves fuel efficiency, and prevents costly breakdowns.

Transmission maintenance involves several critical tasks:

1. Keeping the Air System Clean: Many automated manual transmissions (AMTs) rely on air pressure to engage and disengage gears. Keeping the air system clean and free of moisture and contaminants prevents gear-shifting issues and ensures reliable operation.

2. Lubrication: Regular lubrication checks are essential. Different transmission types have varying intervals for oil changes, which are detailed in manufacturer guidelines. For example, in linehaul applications, an AMT like the Eaton-Cummins Endurant HD can go up to 750,000 miles between lubricant changes, while a manual transmission may require changes more frequently.

3. Preventive Maintenance: This includes checking for leaks, inspecting the clutch, and ensuring there are no unusual noises or vibrations that could indicate potential issues.

A semi-truck maintenance schedule can vary significantly depending on its application so it’s important to have regular truck maintenance to keep your fleet in top shape. Additionally, the type of driving conditions a truck encounters affects transmission maintenance needs. For example:

Catching transmission issues early can prevent expensive repairs and downtime. Some early signs to watch for include:

Modern diagnostics tools, such as Eaton Cummins IntelliConnect remote diagnostics and ServiceRanger 4, can help identify these issues early and streamline the repair process. These tools offer real-time data, helping technicians diagnose and resolve problems more efficiently.

Automated manual transmissions (AMTs) are becoming more common in heavy-duty trucks due to their fuel efficiency and ease of operation. Compared to traditional manual transmissions, AMTs typically have fewer wear points, leading to reduced maintenance requirements. For instance, clutches in AMTs tend to last longer, and lubricant intervals can be significantly extended.

However, both manual and automated transmissions require regular maintenance to ensure optimal performance. The choice between manual and AMT often depends on the truck’s application and the driver’s preference, but understanding the transmission maintenance differences can guide fleet managers in creating a more effective maintenance schedule.

The trucking industry is seeing rapid advancements in transmission technology, with automated and semi-automated systems leading the way. These systems reduce the need for frequent maintenance and are designed to optimize performance based on driving conditions. Features like predictive shifting and integrated telematics help operators monitor transmission health in real-time, reducing the likelihood of unexpected failures.

By incorporating these technologies, fleets can reduce their overall maintenance costs, improve fuel efficiency, and extend the life of their transmissions.

To have the most reliable transmission, consider these best practices:

Maintaining a reliable transmission is essential for keeping your trucks on the road and your business running efficiently. By following a proactive maintenance approach and adapting to advancements in technology, fleet managers can ensure their transmissions remain in peak condition, minimizing downtime and maximizing profitability.